- Customer success story

How EGU Accelerates Lighting Design with Innovative Approach to Space Digitization

digitized projects

digitized rooms

saved on 3D model creation

3D objects created with Metaroom

About EGU

Elektro Großhandels Union Rhein-Ruhr GmbH & Co. KG is a German electrical wholesale company, that provides a wide range of electrical products and services to professionals in the electrical trade, industry, commerce, and public authorities.

INDUSTRY

Electrical wholesale

COMPANY SIZE

300+ employees

LOCATION

Dortmund, Germany

+ 22 branches in North Rhine-Westphalia,

Germany

Introduction

As a leading electrical wholesaler specializing in lighting solutions, EGU’s team develops over 1,000 lighting concepts each year. A crucial part of these projects is modernizing existing lighting systems, but a common challenge we face is the lack of accurate plans. When we first discovered Metaroom platform, we were excited by its potential to optimize our workflow. We quickly realized that this technology could drastically speed up our processes, from on-site measurements to final lighting concepts, making our work more efficient and precise than ever before.

Challenge

Every lighting concept EGU’s team creates is unique and requires a detailed understanding of the existing space before designing an optimized lighting solution. When modernizing lighting systems, an on-site visit is always necessary to assess the current infrastructure, dimensions, and layout. However, this process had several significant challenges for the company:

- Time-Consuming Measurements: A considerable portion of each site visit was dedicated to manually measuring rooms and floors, which was both labor-intensive and prone to human error. Even minor miscalculations could lead to inaccuracies in the lighting plan, requiring follow-up visits and adjustments.

- Manual Documentation Delays: Once back at the office, our team had to manually redraw room layouts based on the collected measurements and photographs. This was not only time-consuming but also created potential gaps in documentation, as any missing data meant revisiting the site.

- Scaling the Process Efficiently: With over 1,000 lighting concepts developed annually, maintaining efficiency across multiple projects was a growing concern. The need for accurate, standardized documentation across different sites added another layer of complexity.

- Limited On-Site Expertise: Not all field representatives are trained lighting designers, meaning they could collect basic information but lacked the tools to capture comprehensive site details needed for a full lighting plan.

We needed a solution that could streamline our work, reduce time spent on-site, minimize errors, and enhance collaboration between field representatives and lighting designers.

| Lighting project.

Solution

To overcome these challenges, we integrated Metaroom into our workflow to enhance efficiency and accelerate project execution. Here’s how Metaroom platform helped us optimize our approach:

- Fast and Accurate 3D Scanning: Instead of spending hours on manual measurements, our team could now scan entire rooms and floors quickly and precisely with Metaroom 3D Scan App, eliminating the risk of missing critical details.

- Seamless Digital Documentation: With Snapshots, automatically captured scan frames, and rapidly generated floor plans, we ensured that all essential data was recorded with one-time scan, minimizing the need for follow-up site visits.

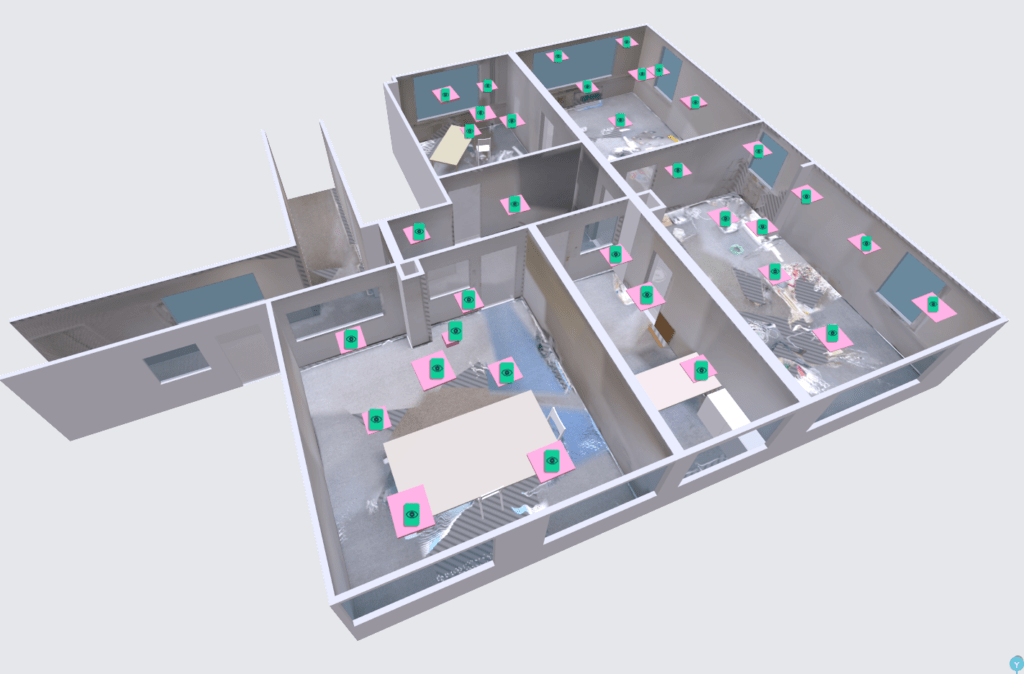

- Direct Integration with DIALux: Exporting scanned room models in .IFC format from Metaroom into DIALux allowed us to work with highly accurate 3D models, speeding up the lighting design process while ensuring compliance.

- Empowering Field Teams: Even non-lighting designers in our field team could now scan rooms, making the process more efficient. Our lighting designers could then access the data remotely to create tailored lighting concepts.

- Professional and Scalable Workflow: Metaroom helped to improve the quality of our documentation and presentations, while also providing a scalable solution for managing hundreds of lighting projects.

With Metaroom, we optimized speed, accuracy, and collaboration within the team. It enables us to deliver better results with less effort.

| 3D model of the scanned space.

Results

By integrating Metaroom into EGU’s workflow, we have increasingly utilized Metaroom’s .IFC 3D models in DIALux, enhancing the efficiency and accuracy of our lighting design projects. Initial challenges were quickly resolved, thanks to excellent support and collaboration with the Metaroom’s team. While window and door representations in the models are simplified, they effectively serve as a basis for normative verifications, such as office lighting compliance.

digitized projects with Metaroom

digitized rooms

saved on 3D model creation

3D objects created with Metaroom

Conclusion

Our experience with Metaroom has been overwhelmingly positive. While it is difficult to quantify the exact time savings, the success we have achieved in implementing projects with Metaroom confirms that we will continue to rely on this solution moving forward.

Following these successes, we have decided to equip more employees with Metaroom solutions, ensuring that our team remains at the forefront of innovation in lighting design.

Lars Domann

“Metaroom is another great step toward the future!”

Lars Domann

Light Planner @ EGU Elektro Großhandels Union